|

|

|

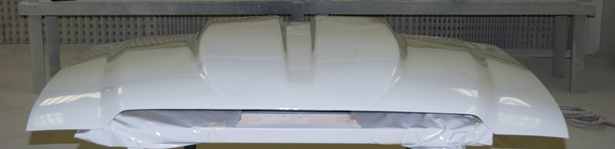

Before!

|

|

So as not to destroy

the factory hood for future use, I purchased an aftermarket

steel replacement hood from CertiFit.com, a National Auto Body

parts supplier. I then

researched and purchased a steel cowl induction scoop made for a

'93 - '97 Ranger and adapted it to the '07 hood. I

purchased it from www.truckn.com,

a supplier of suspension parts and accessories in Mesa, AZ. |

|

I traced the shape

of the scoop onto the hood and cut out a 24" square section

of the hood within the confines of the scoop template. I then

drilled, bonded and pop riveted the scoop onto the hood. After

the bonding adhesive setup, I ground the edges down to make the

transition smoother. In comes Paul Wagner, our prep and paint

guy at work - Paul has the Master's touch with plastic filler.

He recommended MarLite fiberglass reinforced filler putty due

the vibration and heat the hood will endure. He spent about a

day and a half filling and sanding until the hood looked like it

was a one piece cowl induction hood. |

|

Paul then sealed the

entire hood with an epoxy primer /sealer to get it ready for the

Dupont Imron finish coat. I took over from there and put three

medium coats of Ford factory white Imron on the entire hood. My

wife accompanied me to the shop on Sunday afternoon to move it

out of the spray booth for Monday's work schedule. Once we

arrived, she said "when are you going to put it on?" I

said "I'll need another person to help me lift off the old

one and install the new one!" She said "Can't I help

you do it?" Now I remember why I married this woman!

It took us about an hour and we jumped in and headed for the

beach... hope you enjoyed the project! Pictures below... |

|

|

|

I cut the hole approximately 24" X

24"...

should yield plenty of air.

|

|

|

|

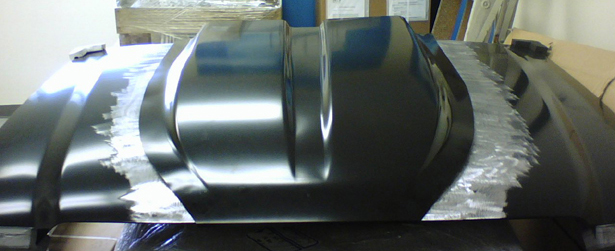

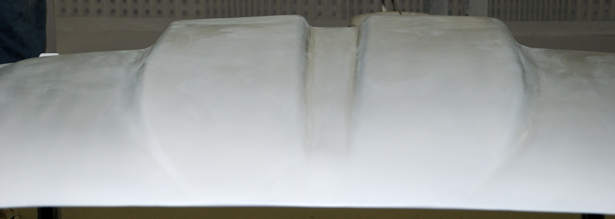

It has a double hump

look due to the center groove!

|

|

|

|

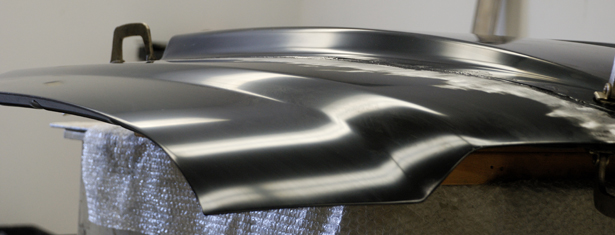

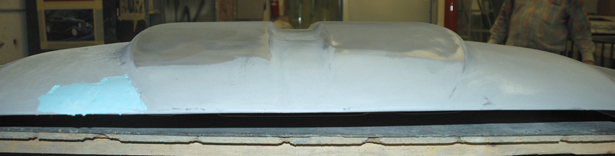

The '93 - '97 scoop

had a slightly different contour... we fixed that! |

|

|

|

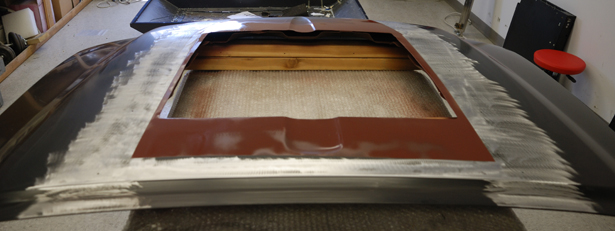

Primed around hole...

can't get to that later!

|

|

|

|

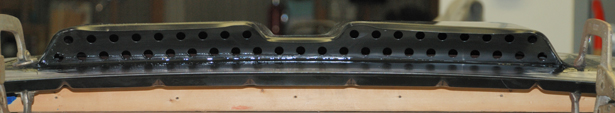

Scoop rear baffle

bonded into place and ready for trimming and fitting.

|

|

|

|

I used 3M "8115 Panel Bonding

Adhesive" and pop-rivets!

|

|

|

|

Bonded... when dry, sand, mud, prime and

paint...

|

|

|

|

Bonded, riveted and drying...

|

|

|

|

Edges & rivets

smoothed and ground down... ready for mud!

|

|

|

|

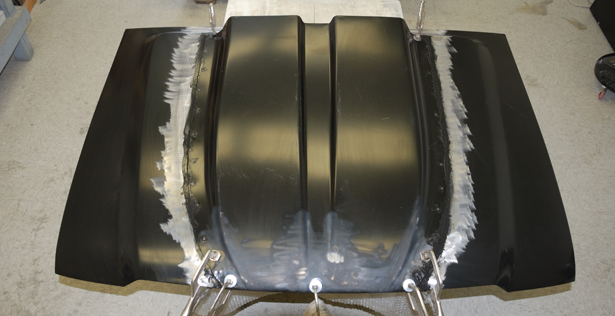

Paul Wagner, our prep guy at

work, sanding the first coat of MarLite reinforced filler...

|

|

the filler has fine

fiberglass strands in it to make it withstand the hood's

vibrations.

|

|

|

|

First coat done and

scored for second coat...

|

|

|

|

Second coat sanded and

spot work added...

|

|

|

|

Seams came out very

nice...

|

|

|

|

...a little more

sanding and prep... |

|

|

|

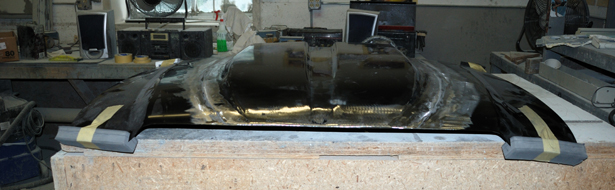

Paul getting ready for

the final coat of primer/sealer. |

|

|

|

Looks much better

white, even if it is primer! |

|

|

|

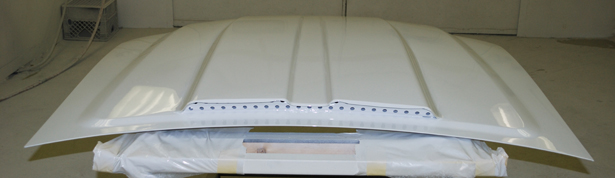

Fresh coat of Dupont

Imron polyurethane enamel... |

|

|

|

Scoop has a built in

baffle for leaves, varmints, etc. |

|

|

|

The scoop offers a conservative

2.5" rise... |

|

|

|

Looks almost factory,

thanks to Paul Wagner's bodywork skills... |

|

|

|

After! |

|

|

|

A little vinyl

lettering from "Signs by Tommorrow" in Norton, MA! |

|

|

|

It gives the truck a

little bit more aggressive look!

|

|